- 2 Minutes to read

- PDF

Cross-Site Moves

- 2 Minutes to read

- PDF

Cross-Site Moves

The Cross-Site Move function is used when you want to move an item or a License Plate from one site to another without the need for a Transfer Order. This process can be committed through both the mobile device as well as the Web Console. Below demonstrates the Cross-Site Move technique through the mobile device. To view how to process a Cross-Site Move through the Web Console see Mass Bin Transfer.

Setting up Cross-Site Moves

To enable Cross-Site moves the user will first need to configure multiple sites in the Web Console. Begin this process by logging into the website and navigating to System Maintenance > Create & Edit Site.

Next, select an existing site from the arrow drop down for which you would like to be able to move Items to via the functionality of the cross-site move.

To the right of the site address details, the user should see 2 checkboxes, one of them being “Allow Cross-Site Moves to this Site.” Check this box.

Finally, click the Update button to commit and save the change.

Processing a Cross-Site Move (Mobile)

Begin by tapping the Move Icon from the main menu. Tapping the “<” icon in the upper left corner will return the user to the Main Menu.

Scan or Enter the LP or Item you wish to move. Tap the OK button to continue.

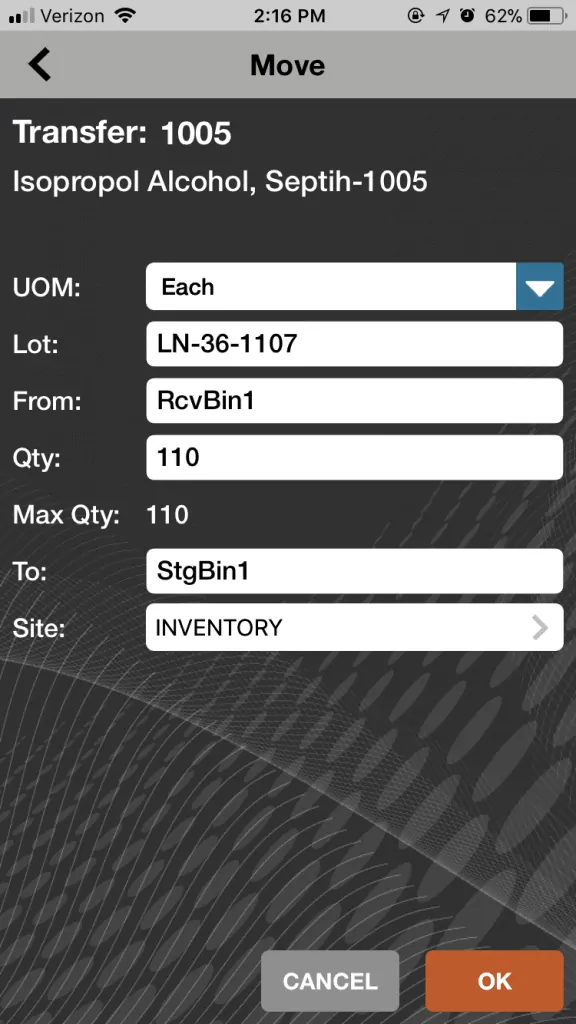

Scan or Enter all the required information. For LPs, this includes just the location, and for Items, it may contain lot/date/serial information, UOM, From Location, Quantity, and To location.

After those fields are entered in, the user will then be prompted to select a Site.

Review the information, and if all looks correct, Tap the OK button.

The Items will now be in the new inventory location found within the specified site.

Item Holds and Bin Transfers

If you move an item/lot which is on hold into the bin with a different item/lot that is not on hold, both records keep their status.

If you move an item/lot which is on hold into a bin where the same item/lot exists, what you move will take that status of what is already there. So, if the item/lot that is moving is on hold and the same item/lot that resided in the bin is not on hold, it will all be off hold. If the item/lot moving is not on hold and that same item/lot which resides in the bin is on hold, that moved quantity will also be placed on the current hold status.

The inventory status is kept at the bin/item/core value level, so for each individual record, a different status can be kept. The core value is used for items that are non-basic like lot, serial, expiration date.